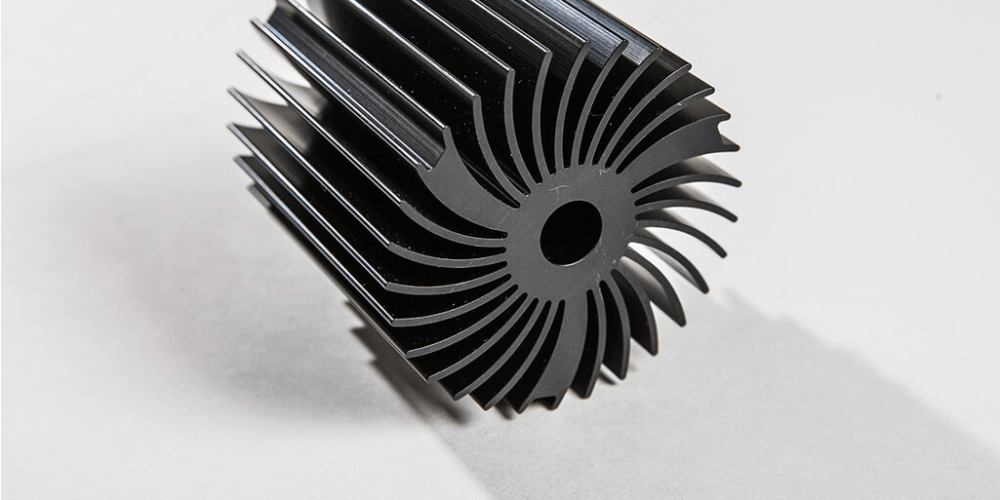

An aluminium extrusion heat sink is a type of heat sink made from extruded aluminium. Heat sinks are used to dissipate heat generated by electronic components such as transistors, diodes, and integrated circuits.

Aluminum is a common material for heat sinks because of its high thermal conductivity, which means it can transfer heat quickly. The extrusion process allows for the creation of complex shapes and designs, which can optimize the heat sink's performance.

The heat sink is made by extruding a block of aluminium through a die to create a profile with fins or other shapes that increase the surface area for heat dissipation. The extruded profile is then cut to the desired length and the surface is finished.

Moreover, aluminum extrusion heat sink is commonly used in electronic devices such as computers, LED lighting, and power amplifiers. They are also used in industrial applications where heat needs to be dissipated from machinery or equipment.

Aluminum extrusion heat sink beginner guide

Sure, here's a beginner's guide to aluminium extrusion heat sinks:

- Understand the basics of heat sinks: Heat sinks are used to dissipate heat generated by electronic components. The heat sink is designed to have a large surface area to dissipate heat quickly, allowing the electronic component to operate within its safe temperature range.

- Know the benefits of aluminium extrusion: Aluminum is a common material for heat sinks because of its high thermal conductivity, lightweight, and corrosion resistance. The extrusion process allows for the creation of complex shapes and designs, which can optimize the heat sink's performance.

- Consider the design factors: The design of the heat sink is crucial to its performance. The fins' height, thickness, and spacing, as well as the shape of the fins, all affect the heat sink's ability to dissipate heat. Other factors to consider include the base thickness, shape, and surface area.

- Understand the manufacturing process: The heat sink is made by extruding a block of aluminium through a die to create a profile with fins or other shapes that increase the surface area for heat dissipation. The extruded profile is then cut to the desired length and the surface is finished.

- Choose the right heat sink for your application: Heat sinks come in different sizes, shapes, and materials. To choose the right heat sink for your application, you need to consider factors such as the amount of heat generated, the available space, and the required airflow.

- Install the heat sink correctly: Installing the heat sink correctly is crucial to its performance. The heat sink should be securely attached to the electronic component using a thermal paste or a thermal pad. The heat sink should also be mounted in a way that allows for efficient airflow.

- Maintain the heat sink: Over time, the heat sink may collect dust and other debris, which can reduce its effectiveness. Regular cleaning can help ensure that the heat sink continues to dissipate heat efficiently.

By following these tips, you can choose and use an aluminum extrusion heat sink effectively for your electronic components.

Lastly, the benefits of using an aluminum extrusion heat sink include its high thermal conductivity. Aluminum has a thermal conductivity of around 200-220 W/mK, which means it can transfer heat quickly. This allows the heat generated by electronic components to be dissipated efficiently and effectively, preventing the component from overheating and potentially causing damage or malfunction. Additionally, aluminum extrusion allows for the creation of complex shapes and designs, which can optimize the heat sink's performance even further.