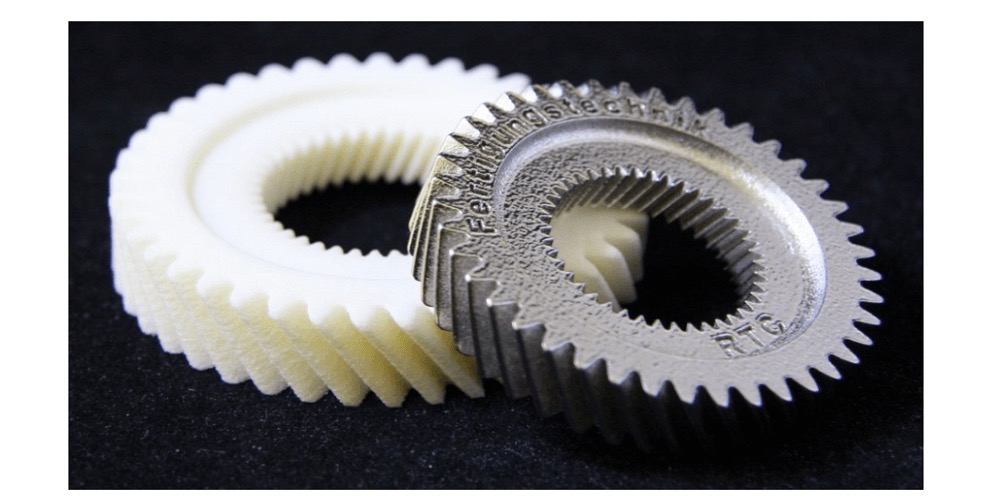

Recent studies have shown that rapid prototyping technology is quite important for both the present and the future. Therefore, if you are in the manufacturing or product development industry, you need to gather adequate information about it. Although it is synonymous with 3D printing, other methods such as CNC machining are widely used. It is also associated with other processes, such as rapid manufacturing and rapid tooling.

It is also cheaper to purchase Rapid Prototyping Services, as many companies and suppliers are offering them. Students and product innovators can make their spare parts from home. Also, it is easier to order rapid prototyping services online. You only need to provide a 3D CAD file, and the manufacturer will produce your rapid prototypes.

Rapid prototyping is an important technique for the quick making of patterns, models, and even simple prototypes. The process starts with creating a 3D data file that provides the desired geometries and tolerances of the product.

Rapid Prototyping Methods

Since the invention of stereolithography, several other processes have been developed. These are the common rapid prototyping methods.

Colorjet

In this method, full-colored plaster layers are joined together with the help of a glue. Since the prototype can be printed in full colors, it effectively makes visual models for marketing and exhibitions.

Stereolithography

Lasers can harden the liquid resin. With this technique, you can make detailed rapid prototypes. Also, stereolithography can be used for making customized parts and products.

Fused Deposition Modeling

This method makes prototypes from molten plastic. Ideally, the process is similar to injection molding. The good thing about this method is that you can make robust models quickly and be done at home.

Selective Laser Sintering

A productive laser is used for the sintering or melting of powdered raw material. This technology is recommended for making functional prototypes. The good thing about this technology is that it offers room for treating the metal.

Other rapid prototyping methods include laminated object modeling, vacuum casting, and space puzzle molding. Your choice of method is dependent on product features and applications.

Benefits of Rapid Prototyping

With rapid prototyping, you can make parts or tools you require quickly. The method is dependent on the chosen methods and size. Also, the complexity of a product and the quality of your design do matter. In most cases, rapid prototyping takes a few days to complete. Prototypes made are used as exhibitions and visualizations that help minimize faulty designs. When you discover the defaults in advance, you can make the necessary changes.

Other than speed to market, rapid prototyping offers other advantages. Since the process involves generative construction, there is minimal wastage as compared to using other techniques, such as grinding, turning, and cutting. Therefore, the process is cost-effective and helps save on other resources, such as labor.

The other reason for the popularity of rapid prototyping is the availability of machines and equipment used for this process. For instance, acquiring rapid prototyping machines is easier and cheaper. That explains why many companies have their 3D printers to make their prototypes and models.