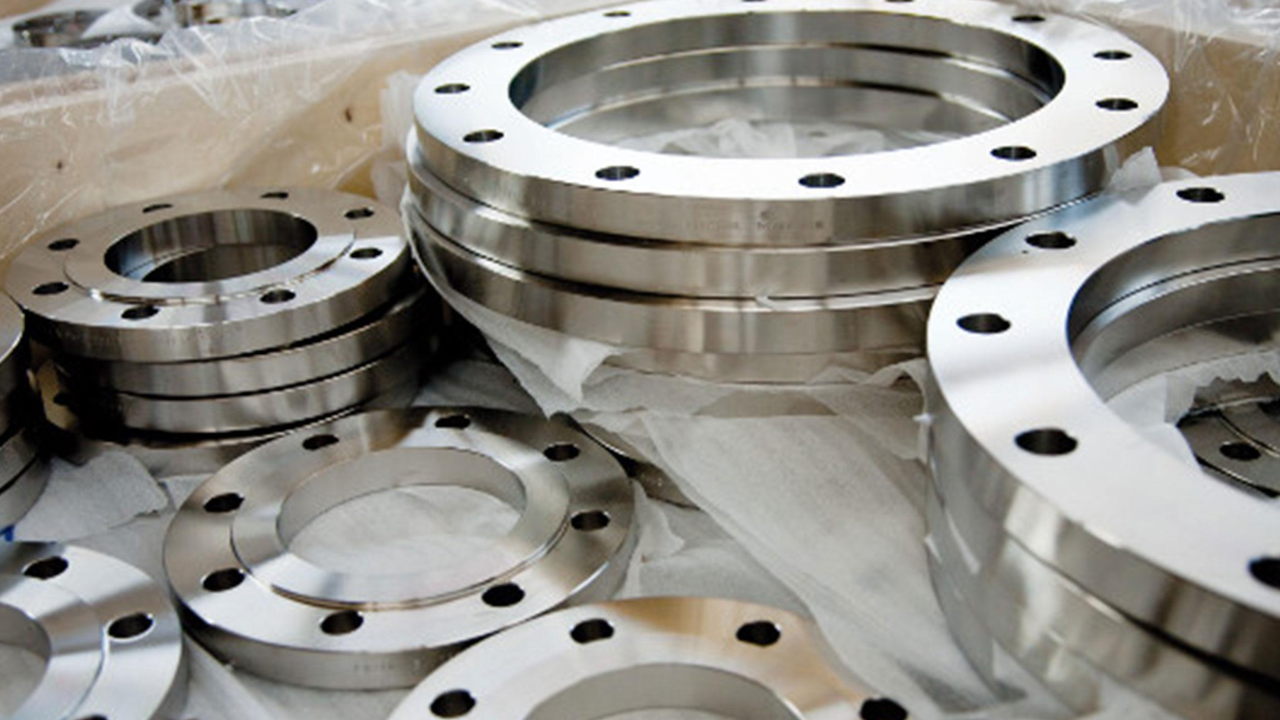

Flanged connectors play an important role in industrial piping systems, connecting pipes, valves, and equipment. The dependability and upkeep of these connections are critical to ensuring the smooth and safe operation of many industrial operations. Flanges, while strong, require consistent care to maintain their effectiveness over time. This article delves into the complexities of guaranteeing the reliability and maintenance of flanged connections.

Reliability is the foundation of any effective pipe system. Flanged connections must withstand a variety of pressures, temperatures, and climatic conditions, making maintenance critical for preventing leaks and failures and assuring overall system integrity. To read more about the rigorous maintenance strategy, see the details below. This method relies heavily on understanding the intricacies of temperature and pressure, properly aligning flanges, and adhering to specified bolting patterns.

Ways to Ensure the Continued Reliability of Flanged Connections

Flanged connections are critical components in piping systems, facilitating the seamless assembly and disassembly of pipes, valves, and other equipment. To ensure the continued reliability of these connections and prevent issues such as leaks and failures, a robust maintenance strategy is essential. This article provides a detailed guide on how to maintain the continued reliability of flanged connections.

❖ Regular Inspection

Regular inspection is critical to ensuring the continuous reliability of flanged connections. Periodic visual inspections reveal wear, corrosion, and deterioration. Bolts, gaskets, and flange faces should all be checked for abnormalities. Early detection allows for prompt intervention, avoiding potential leaks or failures. This proactive strategy guarantees that flanged connections stay in good working order, which contributes to the overall reliability and safety of piping systems in a variety of industrial applications.

❖ Tightening and Torque Checks

Tightening and torque tests are critical to ensuring that flanged connections remain reliable over time. Inspect and tighten nuts regularly to the required torque values to avoid loosening caused by temperature cycling and vibrations. This procedure ensures that flanges are firmly secured, reducing the danger of leaks and improving the overall integrity and longevity of the piping system in a variety of industrial applications.

❖ Gasket Replacement

Gasket replacement is essential for ensuring the continued reliability of flanged connections. Regularly inspect gaskets for wear, deformation, or aging, and replace them as needed. Adhere to manufacturer recommendations for material compatibility and torque values during installation. This proactive approach to gasket maintenance contributes to effective sealing, preventing leaks, and maintaining the integrity of flanged connections in diverse industrial settings.

❖ Surface Preparation

Surface preparation is critical for maintaining the reliability of flanged connectors. Before assembly, thoroughly clean the flange faces to remove old gasket material and impurities. Use the proper tools and processes to obtain a smooth and equal surface. Proper surface preparation improves effective sealing, reducing the danger of leaks while also improving the overall integrity and performance of flanged connections in industrial applications.

❖ Corrosion Prevention

Corrosion prevention is critical to assuring the continuous reliability of flanged connectors. Consider using protective coatings, cathodic protection systems, or corrosion-resistant materials. To increase the life of flanges, monitor them regularly and address any corrosion issues promptly. This proactive corrosion prevention strategy helps to maintain the overall integrity and longevity of flanged connections in a variety of industrial applications.

❖ Temperature and Pressure Considerations

Temperature and pressure issues are critical for maintaining the reliability of flanged connectors. Flanges operating in harsh environments necessitate extra care. Insulation, heat shields, and cooling systems can all help to manage temperature changes. Check if the flanges are rated for specific pressure and temperature conditions. Adherence to these guidelines improves the overall integrity and performance of flanged connections in industrial settings.

❖ Alignment and Bolting Patterns

Proper alignment and adherence to bolting patterns are critical for the long-term durability of flanged connectors. During assembly, verify that the flanges are properly aligned to prevent uneven bolt loading. Use the appropriate bolting patterns to distribute the load uniformly across the flange face. Misalignment can cause leaks and lower reliability, thus, alignment and bolting patterns are important factors in flange maintenance.

Sum Up

Maintaining the dependability of flanged connections is critical for the proper operation of piping systems in a variety of industrial settings. A proactive maintenance approach is essential. Organizations may improve the longevity and dependability of their flanged connections by adding sophisticated technology, detailed record-keeping, and emergency response planning, reducing the risk of costly downtime, environmental impact, and safety issues.