V belts play a central role within industrial and mechanical power transmission because they are the most effective and reliable when it comes to transferring power within challenging surroundings. V Belts are used in numerous heavy-duty applications in agricultural equipment and construction machinery. They are highly dependable components in the establishment of discontinuous mechanical duties due to their strong design, strong frictional grasp, and ability to endure shock loads.

Knowing the Design and the Operation of V Belts

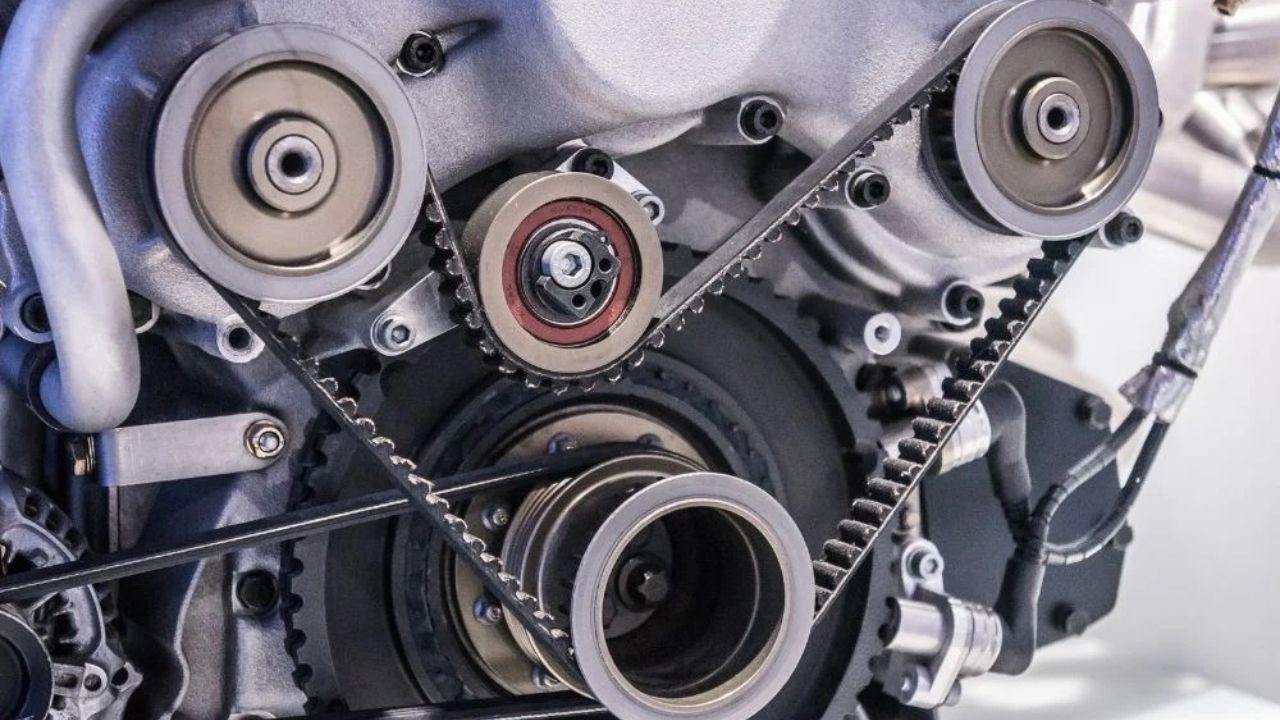

V belts are named so because of their characteristic trapezoidal shape of cross-sectional profile that enables them to fit safely in corresponding V-shaped grooves on the pulley. This design offers a better grip as it achieves more contact between the belt and the pulley, hence allowing the transfer of power effectively without much slippage. A belt grooving causes frictional forces to be generated along the pulley groove, and the tension on the belt when the belt is correctly tensioned provides effective transmission of torque between the driven shaft and the driving shaft.

Most V belts are typically manufactured using high-strength rubber compounds that are reinforced with polyester, aramid, or steel cords, and are engineered to handle high tension, changes in temperature, and extended loads during operation. Their construction gives them the flexibility and strength to bend easily around pulleys, as well as have durability and wear resistance.

Stability Under Heavy Loads

Heavy machinery is usually subject to variables that require a constant and unvarying power supply. Crushers, compressed, tractor, and industrial mixers are some of the equipment that need transmission systems capable of withstanding high torques without failure. V belts are designed to fulfill these very high requirements by providing uniform grip and tension even when faced with sudden changes in load or high operational stress.

The wedging effect of V belts offers a self-tightening feature of the belts, i.e., the higher the load, the tighter the belt would be gripping around the pulley. This is a quality that allows it to lift off without slipping, and it is capable of transferring power even with heavy loads. As opposed to flat belts, which only use friction on their surface, V belts have the advantage of mechanical wedging, which makes them much more appropriate in high-torque applications.

Environmental Factor Resistance and Durability

V belts manufactured using superior rubber materials and synthetic reinforcements are specifically designed to minimize wear and tear from such factors. These belts are flexible in low temperatures, and they do not crack, swell, or harden in hot and oily conditions. The polyester or aramid fibers inner cords give the belt tensile strength and maintain its dimensions when in constant use, as they ensure that no slack occurs, which could cause the belt to lose its shape and tension.

Power Saving and Fluid Movement

V belts are also efficient in energy consumption because they offer smooth and vibration-free operation and are quiet. Such a fine fit between the belt and pulley reduces energy losses through slippage to the bare minimum, and thus most of the power input is effectively transferred to the driven element. Their damping effect and shock loading absorbing property protect the mechanical parts of the machinery against undue wear, which increases the life of the equipment and minimizes the sound produced during operation.

Moreover, the modern V-belt design, like a cogged or notched V-belt, is more flexible and heats less, hence higher efficiency and lower bending stress can be achieved. Such innovations ensure that V belts are suitable for use where the operations to be performed constantly involve high speed and do not compromise on performance or reliability.

Maintenance and Cost Effectiveness

The other factor that makes V belts common in heavy-duty machinery is the capability to maintain them easily and cheaply. V-belt drives also need minimum lubrication and manual adjustment as opposed to complex chain or gear drives. One can change or re-align the belt easily and does not need a lot of downtime or specific equipment.

V belts are highly cost-effective when used in large-scale machines when installed and tensioned properly because they provide a long lifespan in operation. Tension, alignment, and wear inspections can also be used to further increase service life and provide a steady performance with few interruptions.

Applications Within Heavy-Duty Industries

V belts have extensive use in heavy industries that are essential in all sectors of industry. They drive the hydraulic pumps, compressors, and conveyors in construction machinery. V belts are used in agriculture to propel tractors, threshers, and harvesters, which operate effectively in the fields. They are used in manufacturing and mining industries to drive crushers, grinders, and conveyor belts used to move large materials and high torque loads.

Conclusion

The V belts have withstood the test of time as one of the most effective and efficient means of power transmission in heavy-duty machinery. Their special design, capacity to work on high torque, and their durability to work in harsh situations make them an essential ingredient in industrial applications. V belts not only improve the performance of heavy equipment by the provision of stable, smooth, and efficient power transfer, but also minimize downtime and the cost of maintenance operations.